- BY purplepuddle

- POSTED IN Crush

- WITH 0 COMMENTS

- PERMALINK

- STANDARD POST TYPE

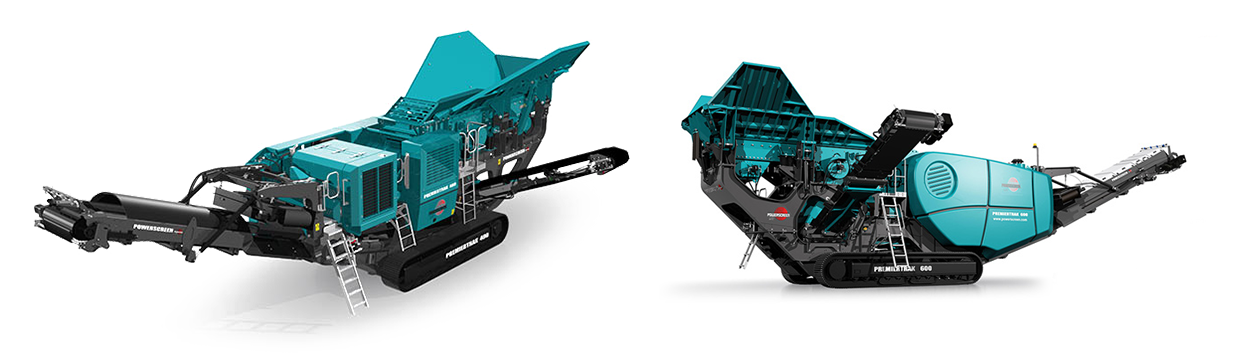

Powerscreen PT400

The Powerscreen® Premiertrak 400 range of high performance primary jaw crushing plants are designed for medium scale operators in quarrying, demolition, recycling & mining applications.

The range includes the Premiertrak 400 with hydraulic adjust & the Premiertrak R400 with hydraulic release. User benefits include track mobility for a quick set-up time, hydraulic crusher setting adjustment for total control of product size & crusher overload protection to prevent damage by un-crushable objects.

Main Advantages

- Output potential up to 400tph (440 US tph)

- Hydraulic folding feed hopper with wedge fixing system

- Heavy duty wear resistant feed hopper

- Stepped self-cleaning grizzly feeder with under feeder screen option

- Deep fines chute to reduce material blockages

- Aggressive crushing action with high swing jaw encouraging material entry into crushing chamber

- Hydraulic crusher setting adjustment

- Improved manganese liner retention, protects jaw supports on both swing & fixed jaws

- Excellent under crusher access for removal of wire with hydraulic raise lower product conveyor

- Angle adjustable product conveyor, 3.9m discharge height, lowers for transport

- Low fuel consumption due to highly efficient direct drive system

- Easy access power unit canopy

- PLC control system with auto start facility

- Remote control via umbilical

- Dust suppression system

- Easily set up